2021 High quality Metal Detector - Metal detector (China Supplier Fish Meal Metal Detector Machine) – Fanxiang

2021 High quality Metal Detector - Metal detector (China Supplier Fish Meal Metal Detector Machine) – Fanxiang Detail:

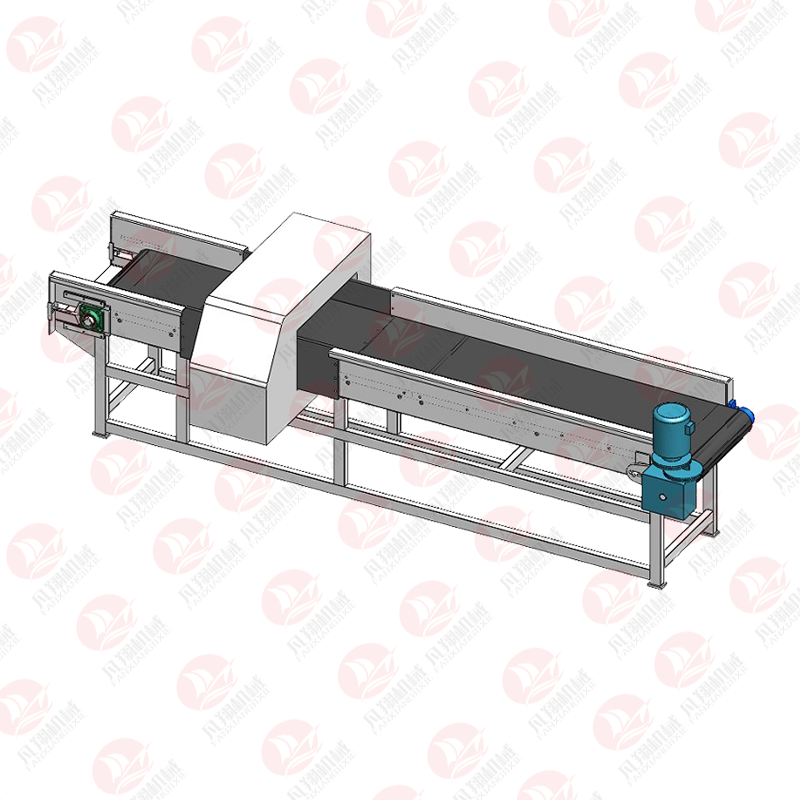

working principle

The raw material will inevitably be mixed with metal, and once the metal into the production line, it will cause damage to the equipment. In order to ensure the normal operation of the production line, it is very important to remove the metal in the raw fish.

Metal detector is used to solve the above problems, its working principle is:

when the raw material passes through the detection channel of the metal detecting head, it falls into the bottom screw conveyor, which keeps turning in a positive rotation direction and sends the raw material to the next equipment in the production line. Once the metal material is detected in the passing raw material, the metal detection control system immediately manipulates the bottom screw conveyor to implement the reverse action and send the metal and part of the raw material to the rear exit. After the completion of the above work, it will automatically return to the normal detection and conveying working state, so as to realize the purpose of the raw material for metal detection.

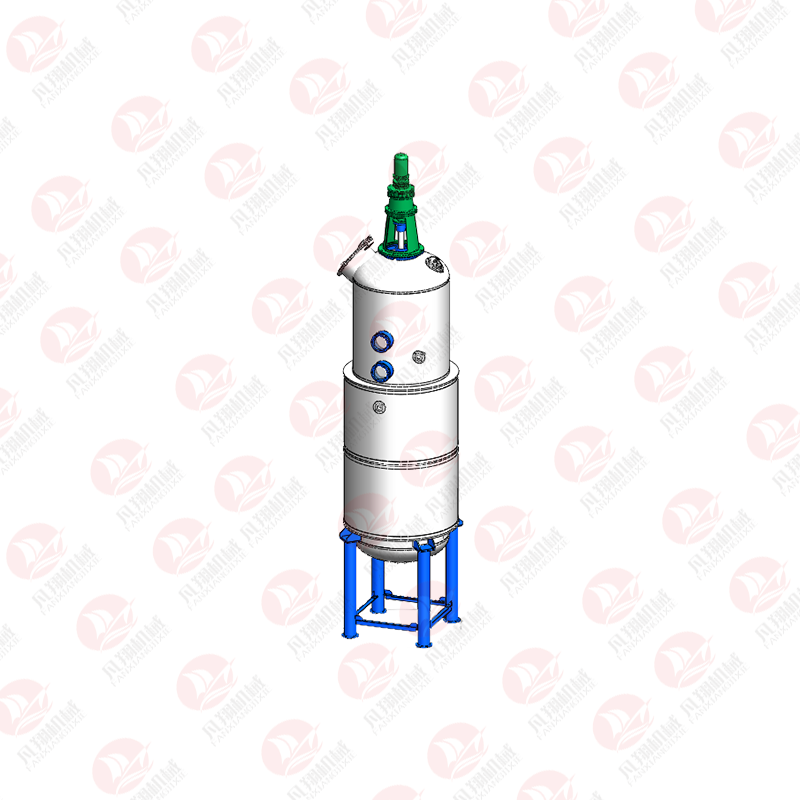

Structure

|

No. |

Description |

No. |

Description |

|

1. |

Metal detection head |

3. |

Screw conveyor |

|

2. |

Conveyor input |

4. |

Basement |

(1)Metal detection head

Metal detection head is used to detect metal impurities in the material, in different working conditions can set different metal detection sensitivity, to meet the needs of different working conditions.

(2)Screw Conveyor

The screw conveyor is used to convey the raw material after the metal detector channel. The positive direction realizes the normal conveying of the raw material; when the raw fish is mixed with metal impurities, the convey will take reverse rotation, then the metal impurities will be pushed out from the other exit together with some materials. The positive and reverse movement of the screw conveyor is controlled automatically by the metal detectors according to the actual working condition.

(3)Basement

The basement is a bracket used to support the fixed metal detector head and screw conveyor.

Installation collection

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for 2021 High quality Metal Detector - Metal detector (China Supplier Fish Meal Metal Detector Machine) – Fanxiang , The product will supply to all over the world, such as: Kuala Lumpur, Argentina, New Zealand, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.