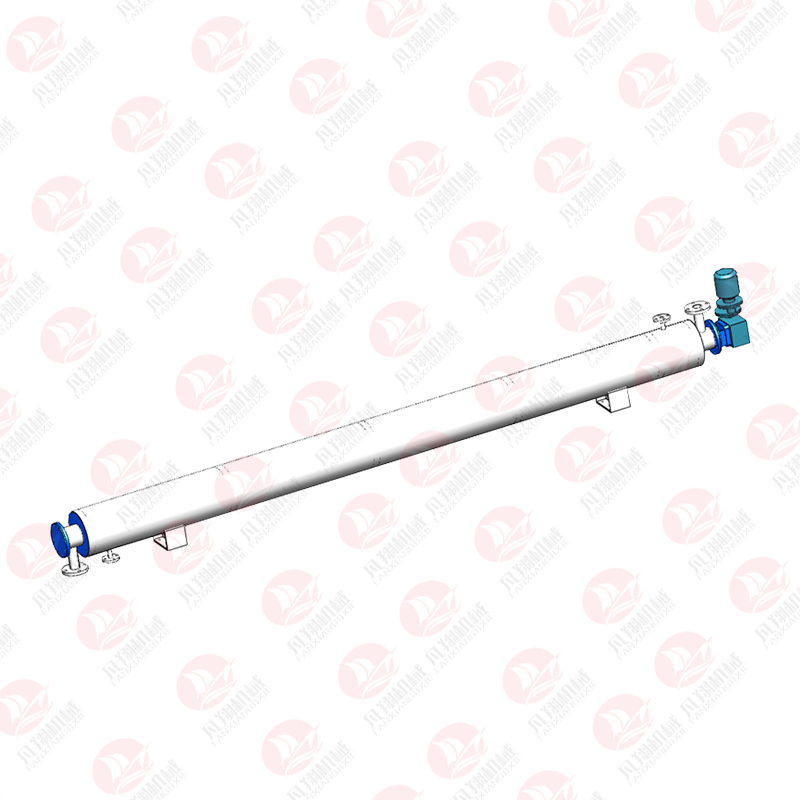

Factory Supply Fish Oil Decanter Centrifuge - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang

Factory Supply Fish Oil Decanter Centrifuge - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power(kw) |

||

|

L |

W |

H |

||

|

SJRQ-Ø219*3000 |

3000 |

380 |

640 |

0.25 |

|

SJRQ-Ø219*4000 |

4000 |

380 |

640 |

0.25 |

working principle

The protein water extruded from the Screw Press must be preheated before entering the Tricanter, and the temperature can be controlled at 90℃~95℃, which is conducive to the separation of oil and water. The working principle of Protein Water Heater is to heat protein water by indirect heat exchange between steam and protein water. The steam enters the shell insulation cover from the steam inlet of the power end, and the protein water enters the main shaft of Protein Water Heater from the non-power end. After indirect heat exchange between steam and protein water, the condensate water generated in the heat exchange process is discharged from the condensate outlet at the bottom of the non-power end, and the heated protein water is discharged from the outlet at the power end and then fed into the Tricanter for centrifugal separation. Steam and protein water enter the Protein Water Heater from opposite directions in order to achieve better heating effect, so that the temperature of the protein water discharged from the outlet is the highest.

Structure

|

No. |

Description |

No. |

Description |

|

1. |

Protein water inlet flange |

5. |

Spindle joint |

|

2. |

Condensed water outlet flange |

6. |

Steam inlet flange |

|

3. |

Foot stand |

7. |

Protein water outlet flange |

|

4. |

Barrel-body parts |

8. |

Insulation cover |

Installation collection

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Factory Supply Fish Oil Decanter Centrifuge - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang , The product will supply to all over the world, such as: Vietnam, Sevilla, Macedonia, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We're able to also give you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and items, make sure you speak to us by sending us emails or call us quickly. In an effort to know our merchandise and company extra, you may come to our factory to view it. We'll generally welcome guests from all over the world to our business to create business relations with us. Be sure to feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.