Factory Supply Vacuum Drier - Screw Press (High Quality Double Screw Press Fishmeal Processing Machine) – Fanxiang

Factory Supply Vacuum Drier - Screw Press (High Quality Double Screw Press Fishmeal Processing Machine) – Fanxiang Detail:

|

Model |

Capacity (t/h) |

Dimensions(mm) |

Power (kw) |

||

|

L |

W |

H |

|||

|

SY-50T |

﹥2.1 |

5500 |

1400 |

1770 |

15 |

|

SY-80T |

﹥3.4 |

5550 |

1500 |

1775 |

15 |

|

SY-100T |

﹥4.2 |

5620 |

1500 |

1775 |

18.5 |

|

SY-150T |

﹥6.3 |

6100 |

1665 |

1880 |

22 |

|

SY-200T |

﹥8.4 |

6440 |

1665 |

1880 |

22 |

|

SY-300T |

﹥12.5 |

7700 |

1930 |

2085 |

37 |

|

SY-400T |

﹥16.7 |

8671 |

1780 |

2481 |

55 |

|

SY-500T |

﹥20.8 |

9300 |

1780 |

2481 |

75 |

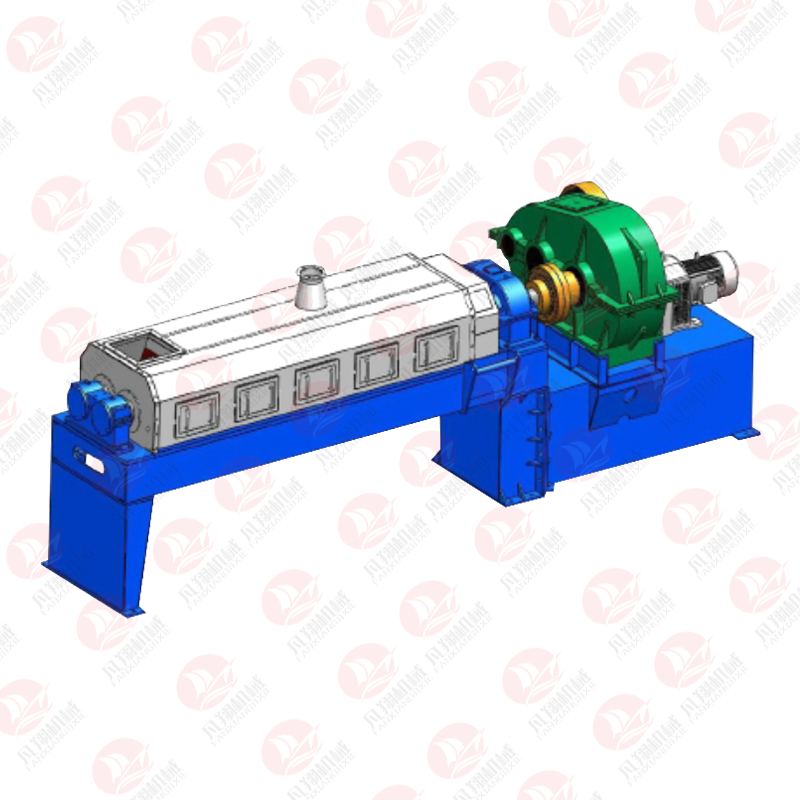

working principle

The function of the Screw Press is to squeeze out the stick water in the solid phase pressed cake as much as possible, which is not only important to improve the yield of fish oil and the quality of fish meal, but also to reduce the moisture content of the pressed cake as much as possible, so as to reduce the workload of the Drier and improve the production capacity of the equipment.

The cooked material is fed from the feed port, and as the pitch of the twin screws of the press gradually decreases along the discharge end while the diameter gradually increases, the raw material located in the screw grooves of the two shafts is gradually compressed, generating a pressure of up to 15kg/cm2 or more. In this process, due to the interaction of the twin screws, it not only prevents the raw material from rotating with the shaft, but also strengthens the mixing and shearing effect on the raw material, which is conducive to the dehydration and degreasing of the raw material. As the raw material is continuously compressed, the stick water continuously flows out from the sieve hole of the stainless steel mesh plates, collects in the liquid receiver hopper and flows from the outlet into the stainless steel protein water tank; while the pressed cake falls from the outlet and is conveyed by the screw conveyor into the Drier.

Installation collection

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for Factory Supply Vacuum Drier - Screw Press (High Quality Double Screw Press Fishmeal Processing Machine) – Fanxiang , The product will supply to all over the world, such as: Austria, Auckland, Islamabad, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.