Fast delivery Heavy Bag Packing Machine - Sieve screening (High Quality Fish Meal Sieve Screening Machine) – Fanxiang

Fast delivery Heavy Bag Packing Machine - Sieve screening (High Quality Fish Meal Sieve Screening Machine) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power (kw) |

||

|

L |

W |

H |

||

|

SJ1000*Ø16 |

2130 |

2490 |

1582 |

1.5 |

|

SJ1000*4M |

5483 |

2507 |

1766 |

3.7 |

|

SJ1000*5M |

6293 |

2547 |

1742 |

3.7 |

|

SJ1000*7M |

8230 |

1450 |

3315 |

7 |

|

SJ1000*8M |

9031 |

3239 |

1742 |

7 |

working principle

There are many types of sieve screening used for fish meal industry, mainly swinging screen, rolling screen and vibrating screen. What we provide is a round drum type sieve screening.

The screen body is round drum type, and there is a spiral arrangement of meal pushing plate welded at the cylinder inside the sieve cylinder, covered with two layers of screen mesh. When the fish meal enters the sieve cylinder, due to the rotary effect of the sieve cylinder, the fish meal slides and rolls continuously on the screen mesh. Most of the fish meal that meets the particle size requirements enters the hopper through the screen holes evenly, and is sent out by the screw conveyor installed at the outlet of the hopper. Due to the impurities and shells and other materials which are larger in shape and size cannot pass through the sieve holes, they fall into the collection cover under the action of the pushing plate in the sieve cylinder body, so as to complete the screening work.

This kind of Sieve Screening are widely used in the world, we have fixed buyers, which are come from India, Russian, Mauritania, Vietnam. We hope we can get a letter of inquiry from you. We can supply semi-product and final-product based on your requirement.

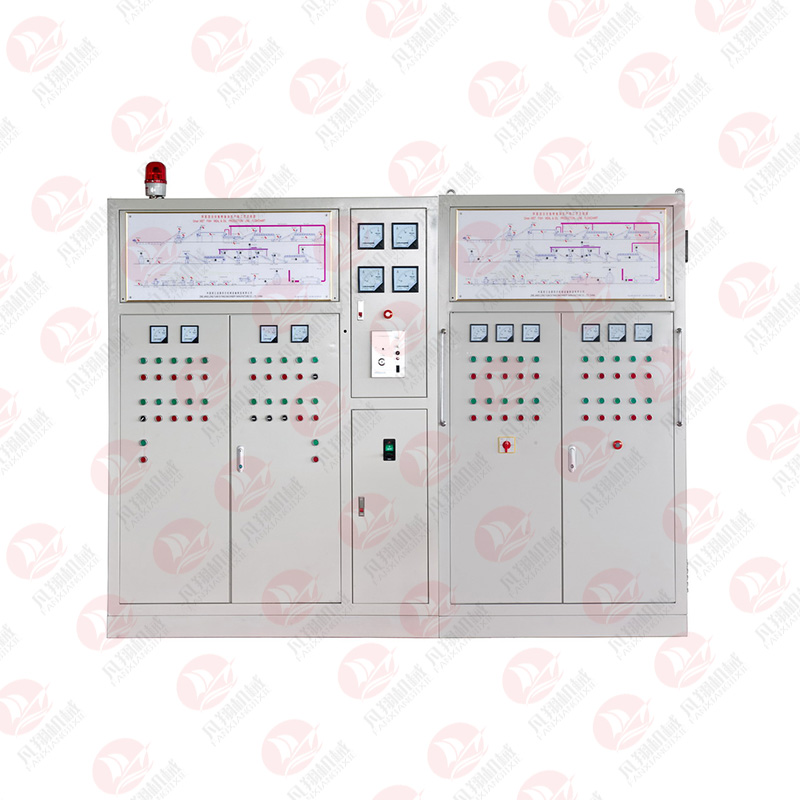

Installation collection

Product detail pictures:

Related Product Guide:

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Fast delivery Heavy Bag Packing Machine - Sieve screening (High Quality Fish Meal Sieve Screening Machine) – Fanxiang , The product will supply to all over the world, such as: Estonia, Jeddah, Tanzania, So far our products have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!