Good Quality Business Extending – Fishmeal Production Machine Spiral Blade – Fanxiang

Good Quality Business Extending – Fishmeal Production Machine Spiral Blade – Fanxiang Detail:

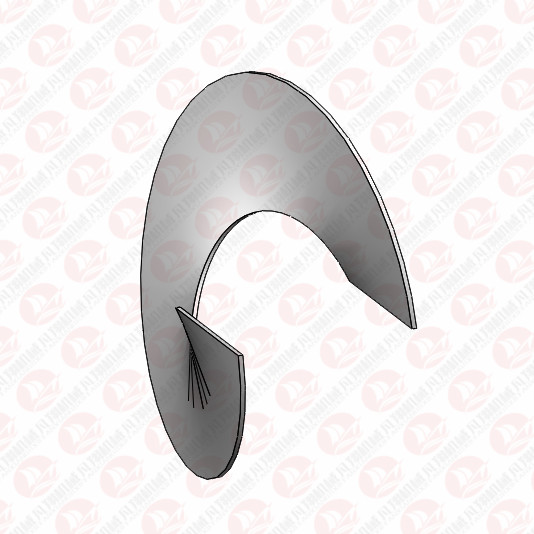

Our company can produce different specifications of spiral blades to meet the different needs of customers. As we all know, the spiral blade is mainly used for conveying materials with high viscosity and compressibility. This spiral surface type, in the process of completing the conveying operation, has the function of mixing the material at the same time. Our company mainly adopts cold rolling and casting method to produce spiral blades, which has the advantages of high production efficiency, saving raw materials, good quality, high hardness, good wear resistance and so on. It is mainly used in various specifications of conveyor and press main shaft.

How to fabricate this spiral? According to the customers’ requirement, like basic material, spiral diameter, spiral distance etc. We will prepare the material and technical drawings, once the spiral blades are ready, the most important step is coming, which is the joint-welding between the blades, before welding, we will make a groove at the joint point firstly, then start welding, by this way, we can guarantee then strength of the whole spiral blades, as we know, the spiral blades are transport the machine by running, if the joint point is not strong, it will be broken easily. According to buyers’ requests, we also can coat alloyed steel plate on the edge of spiral blade to enhance the strength of the spiral blades and make it much more anti-corrosive.

This kind of spiral blades are widely used in the world, we have fixed buyers, which are come from India, Russian, Mauritania, Vietnam. We hope we can get a letter of inquiry from you. We can supply semi-product and final-product based on your requirement.

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Good Quality Business Extending – Fishmeal Production Machine Spiral Blade – Fanxiang , The product will supply to all over the world, such as: Bulgaria, Johor, Vietnam, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.