Hot-selling Heat Exchange For Waste Vapor Condensate - Fishmeal Production Line Deodorizing Tower – Fanxiang

Hot-selling Heat Exchange For Waste Vapor Condensate - Fishmeal Production Line Deodorizing Tower – Fanxiang Detail:

working principle

Deodorizing Tower is cylindrical equipment, vapors move upwards from the bottom, while the cooling water (≤25℃) is sprayed out from the top sprayer like a water film. There is latticed plate at the bottom to put porcelain rings, for release the moving speed of air flow and water flow, meanwhile form a liquid film when the water falls on the ring surface, thus increase the contact area between water and vapors, extent the contact and soluble period, which is help for increasing the absorption of vapors. The cooling water with absorbed vapors flows out from the bottom draining pipe; the remaining vapors that not soluble or absorbed by the water is out from the top, and led into the boiler for high-temperature burning treatment through the pipeline. If the environment permits, the little vapors can be directly discharged.

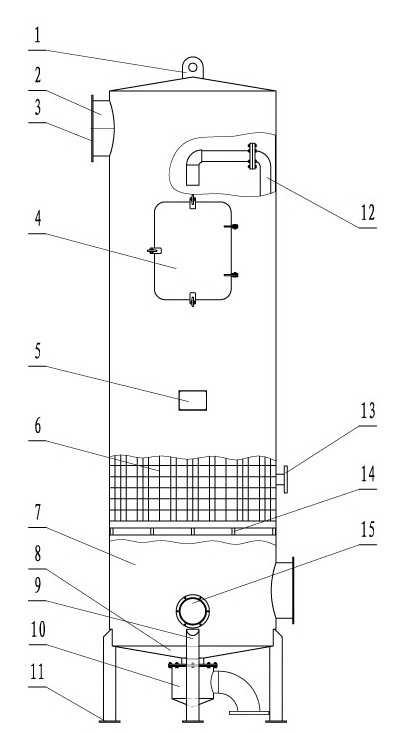

Structure Introduction

|

No. |

Description |

No. |

Description |

|

1. |

Lifting device |

9. |

Stand |

|

2. |

Input & output pipeline |

10. |

Seal for water |

|

3. |

Flange of input & output pipeline |

11. |

Bottom board of stand |

|

4. |

Manhole device |

12. |

Cooling water pipe |

|

5. |

Logo and the base |

13. |

Flange of cooling water pipe |

|

6. |

Porcelain |

14. |

Grid board |

|

7. |

Deodorizing tower body |

15. |

Sight glass |

|

8. |

Deodorizing tower end cover |

The Deodorizing Tower mainly consists of main body, sprayer, and porcelain ring.

⑴ The crust of Deodorizing Tower is a stainless steel made closed cylinder design. There are vapors inlet and outlet on the up and down ends of the crust, a manhole at the front side for maintenance. The latticed plate for holding the porcelain ring is fixed inside the tower.

⑵ The sprayer is fixed on the top of inside tower, it is used to distribute the cooling water like a water film, so as to assure the deodorizing effects.

⑶ The porcelain ring is regularly put inside the tower. Because of the several layers, the vapors pass through the gap, thus increasing the contact area between vapors and cooling water, thereafter, good for the absorption and solution of vapors.

Installation collection

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Hot-selling Heat Exchange For Waste Vapor Condensate - Fishmeal Production Line Deodorizing Tower – Fanxiang , The product will supply to all over the world, such as: Bandung, Malta, Roman, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.