Low price for Fish Oil Processing Line - Centrifuge ( Manufacturers Direct Selling Centrifuge Machine) – Fanxiang

Low price for Fish Oil Processing Line - Centrifuge ( Manufacturers Direct Selling Centrifuge Machine) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power(kw) |

||

|

L |

W |

H |

||

|

DHZ430 |

1500 |

1100 |

1500 |

11 |

|

DHZ470 |

1772 |

1473 |

1855 |

15 |

working principle

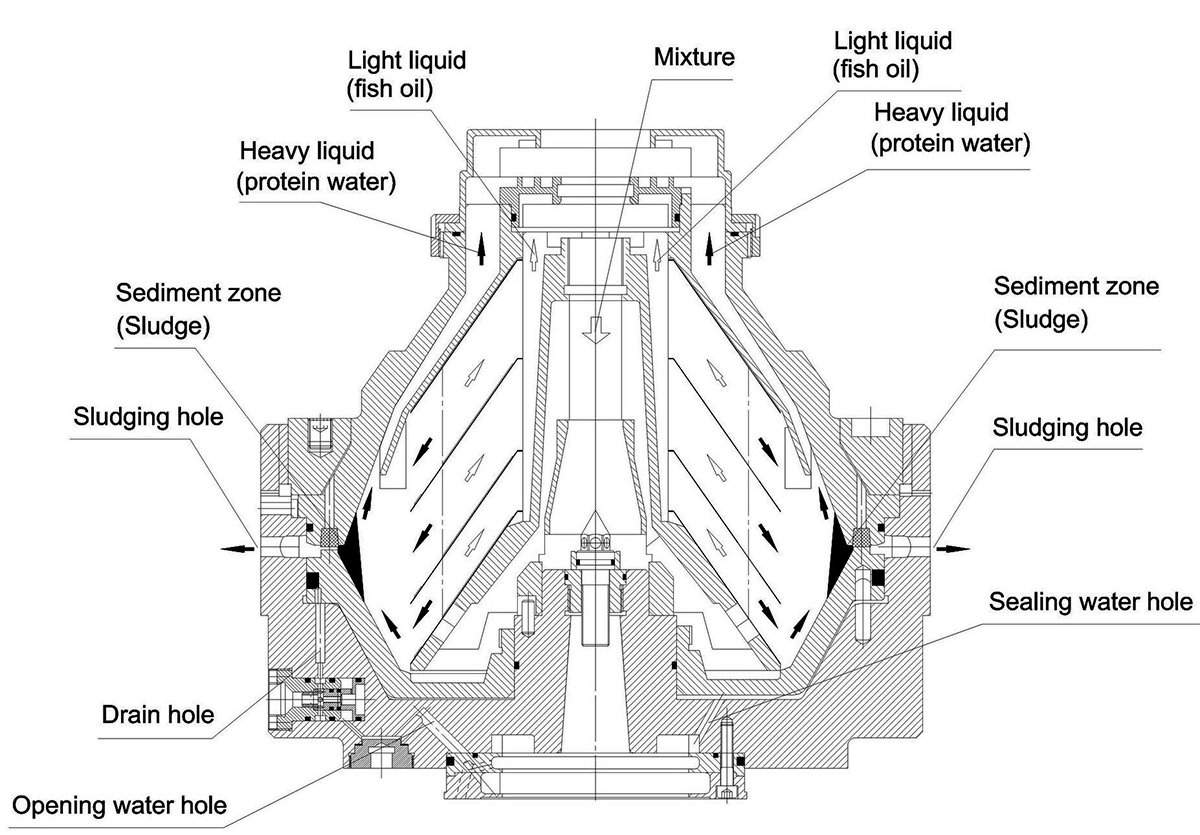

Three solenoid valves are controlled automatically by the PLC intelligence control instrument. Customer may input the control time by oneself according to the demand by the PLC intelligence control instrument manual. When the control instrument is at automatic work appearance, the solenoid valve used in sealing water is opened by the control instrument once every minute to add the water. This water is entering from the water distributor, to the space between the bowl and the sliding piston. Lift the sliding piston by the centrifugal force of the water. Make upper surface of the sliding piston to press the gasket on the bowl top, complete seal, at this time start feeding. When de-slugging, opening water is entering from the water distributor to opening hole, push small piston slide ended, make sealing water flow out from the discharge nozzle, then the sliding piston falls, solid impurities in sediment holding space are ejected from the sediment ejection ports by centrifugal force. Then immediately fill the sealing water, sliding piston seals again. Simultaneity the solenoid valve used in washing water is opened, flush solids in the hood. The process is made by PLC intelligence control instrument, feeding needn’t stop.

The separation is done among the cone-shape discs. The mixture goes into the bowl center through the feeding pipe, and then gets to the discs group after passing through the distribution hole. Under the strong centrifugal force, the light phase (fish oil) flows towards the center along the discs outside surface, keep upwards in the middle channel, and discharged from fish oil outlet by centripetal pump. While the heavy phase (protein water) moves outwards along the discs inside surface, and upwards in the outer channel, and discharged from protein water outlet by centripetal pump. Small amount of solid (sludge) is taken with protein water, most is thrown to the bowl inner wall, gathered in the sediment zone, after a certain time, regularly discharged from sludging hole by means of the piston down.

The centrifuge adopts self de-slugging and centripetal pump. Thus the machine can work continuously for a long time, attain good separation effects in long run.

The sludging ways are auto-sludging, partially sludging and fully sludging. Generally, fully sludging is done when the separation is nearly finished; partially sludging is done when auto-sludging can’t get a well separation, normally the intervals should more than 2 mins and the current is normal rate, after partially sludging, should reset the auto-sludging time.

Installation collection

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Low price for Fish Oil Processing Line - Centrifuge ( Manufacturers Direct Selling Centrifuge Machine) – Fanxiang , The product will supply to all over the world, such as: Argentina, Stuttgart, Iceland, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!