Manufacturing Companies for Centrifuge For Fish Oil Separator - Tricanter ( High Quality Fish Oil Fish Meal Extraction Tricanter Machine) – Fanxiang

Manufacturing Companies for Centrifuge For Fish Oil Separator - Tricanter ( High Quality Fish Oil Fish Meal Extraction Tricanter Machine) – Fanxiang Detail:

|

Model |

Capacity (L/h) |

Dimensions (mm) |

Power (kw) |

||

|

L |

W |

H |

|||

|

LWS355*1600 |

5000 |

3124 |

900 |

1163 |

24 |

|

LWS420*1720 |

6000 |

3500 |

1000 |

1100 |

29.5 |

|

LWS500*2120 |

7000 |

4185 |

1300 |

1436 |

41 |

|

LWS580*2350 |

8000 |

4330 |

1400 |

1490 |

60 |

working principle

Tricanter makes use of the difference of specific gravity between solid and liquid and the effect of centrifugal force field with thousands of times of gravity to make solid fish residue settle quickly and effectively, so as to achieve the purpose of separation.The working principle of the machine is as follows:

The machine starts to rotate at full speed. The material to be separated enters the inner wall of the high-speed rotating drum through the feed pipe and enters the accelerating chamber of the spiral pusher. Because of the different proportion of light liquid phase – heavy liquid phase – insoluble solid phase in the material, the centrifugal force of the three-phase material is different.Insoluble solid phase by biggest by centrifuge maximum subsidence to the wall outside (most), minimum light liquid phase due to the centrifugal force and the settlement to (the) farthest from the drum wall, heavy liquid phase in the midst of it a insoluble solid phase with the drum has a relative differential spiral pusher and is being exhausted from port solid-phase discharging.The light and heavy liquid phases are separated by different structures in the machine, of which the light liquid phase is discharged through the centripetal pump and the heavy liquid phase is discharged through gravity, so as to achieve the purpose of three-phase separation of materials.The light and heavy liquid phases of the three-phase horizontal centrifuge equipped by us are discharged by centrifugal force and gravity respectively, so as to effectively avoid the incomplete material separation caused by miscibility of the material. The ordinary three-phase horizontal centrifuge often results in incomplete separation due to the unstable components of the light and heavy liquid phases at work.The Tricanter introduced by us can adjust the interface of the light and heavy liquid phase according to the change of the composition of the material when the machine is working, so as to achieve the best separation effect of the material.

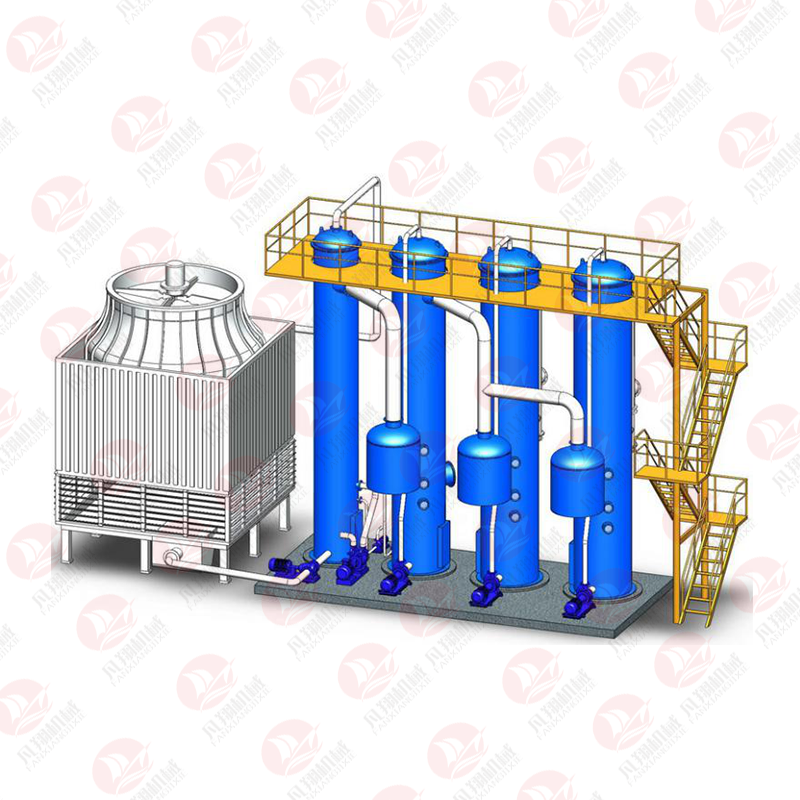

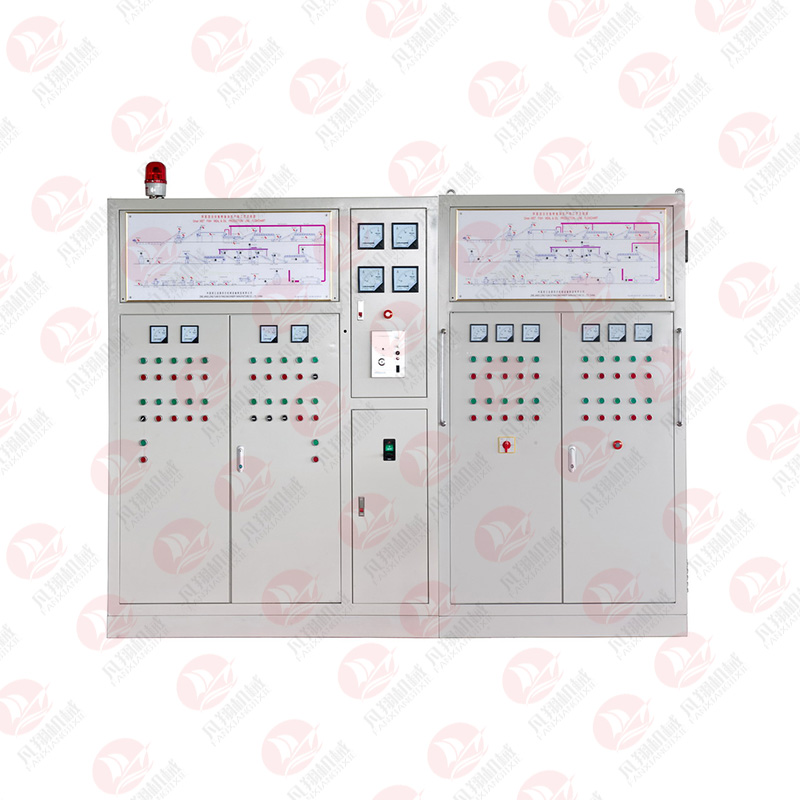

Installation collection

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Manufacturing Companies for Centrifuge For Fish Oil Separator - Tricanter ( High Quality Fish Oil Fish Meal Extraction Tricanter Machine) – Fanxiang , The product will supply to all over the world, such as: Ecuador, Bulgaria, United Arab Emirates, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.