PriceList for Waste Vapor Treating Equipment For Fish Meal Plant - Fishmeal Production Line Blower – Fanxiang

PriceList for Waste Vapor Treating Equipment For Fish Meal Plant - Fishmeal Production Line Blower – Fanxiang Detail:

|

Model |

Dimensions (mm) |

Power (kw) |

||

|

L |

W |

H |

||

|

9-19NO8.6C |

2205 |

1055 |

1510 |

30 |

|

9-19NO7C |

2220 |

770 |

1220 |

15 |

|

Y5-47NO5C |

1925 |

830 |

1220 |

11 |

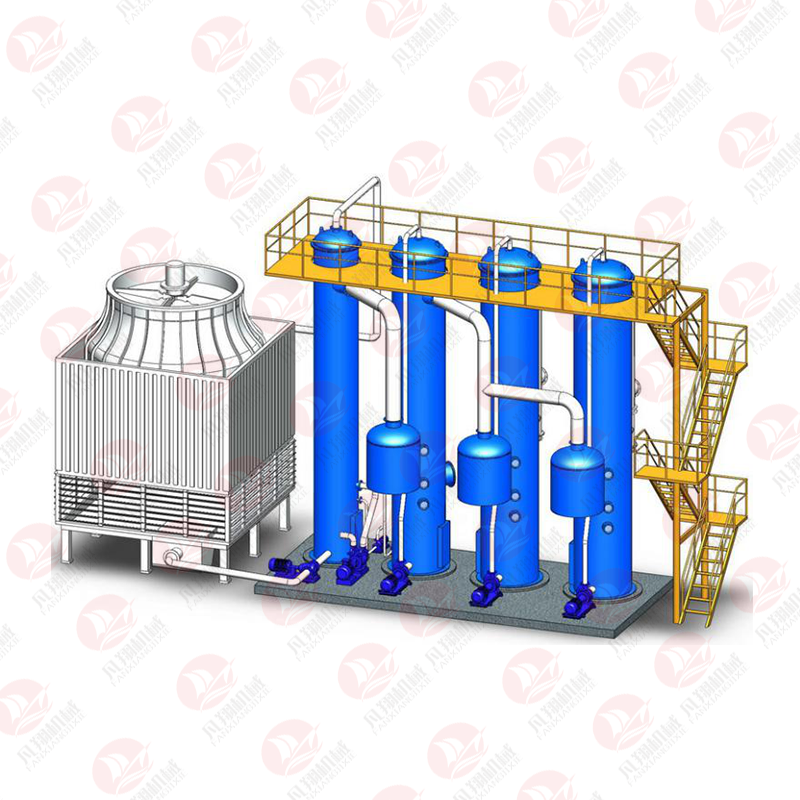

working principle

The vapors transportation is carried out by the Blower. The impeller with several curved fan blade is fixed on the Blower main shaft. The fan blade makes the impeller rotating in the crust driven by motor, so the waste vapors enter into the impeller center from inlet vertically along with the shaft, and pass through the fan blade. Because of the centrifugal force from the fan blade rotating, the vapors are discharged out from the Blower outlet. For the impeller working continuously, the Blower sucks and discharges the vapors continuously, in such way to complete the transportation work of vapors.

Structure Introduction

|

No. |

Description |

No. |

Description |

|

1. |

Motor |

3. |

Main body |

|

2. |

Basement |

4. |

Outlet unit |

Use And Maintenance

There are two lubricating points, i.e. the roller bearing at the two ends. Lubricate the roller bearing by High temperature grease. Because of high speed, the lubrication should be done once per shift, and replaced after using every half year.

The technical inspection should be done after every time stop, and also during running period.

⑴ Check the condensate water draining pipe at the Blower bottom, avoid it to be block, otherwise water logging inside the Blower crust.

⑵ During the Blower running period, check the bearing temperature is normal or not, its temperature rise should be less than 40℃.

⑶ When the v-belt is worn after long time running, replace it for the sake not affect the effects.

⑷ Check the current during the running period, it should not over the motor rated value, otherwise damage the motor. Control the value by adjusting the vapors inlet opening.

Installation collection

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for PriceList for Waste Vapor Treating Equipment For Fish Meal Plant - Fishmeal Production Line Blower – Fanxiang , The product will supply to all over the world, such as: Uzbekistan, Senegal, Israel, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

We have been looking for a professional and responsible supplier, and now we find it.