Quality Inspection for Fish Processing Equipment For Poultry Feed - Cooler (Competitive Price Fish Meal Cooler Machine) – Fanxiang

Quality Inspection for Fish Processing Equipment For Poultry Feed - Cooler (Competitive Price Fish Meal Cooler Machine) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power (kw) |

||

|

L |

W |

H |

||

|

FSLJØ1300*8700 |

10111 |

2175 |

5162 |

29.5 |

|

FSLJØ1500*8700 |

10111 |

2615 |

5322 |

41 |

|

FLJØ1300*8700 |

10111 |

2175 |

5162 |

29.5 |

|

SLJØ1300*8700 |

10111 |

2175 |

2625 |

18.5 |

|

SLJØ1500*8700 |

10036 |

2615 |

3075 |

30 |

working principle

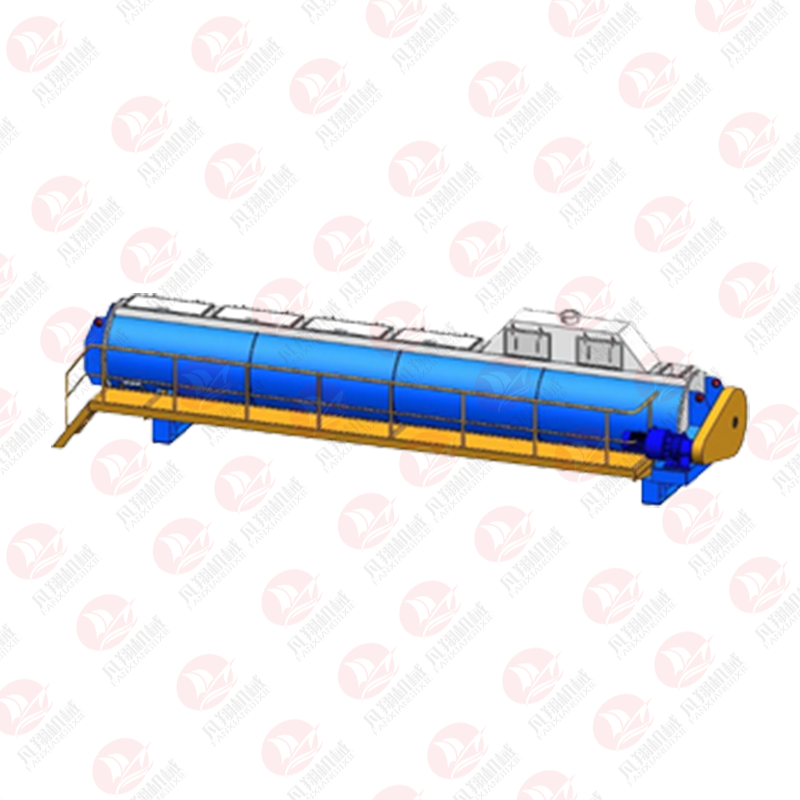

The fish meal comes out of the Drier at a higher temperature. After passing through the Sieve Screening and the Air-cooling Conveyor, some of the heat can be dissipated, but the temperature will still be around 50°C. Due to the violent friction and crushing effect during the crushing process, the temperature of fish meal will rise further. At the same time, because the temperature difference between fish meal and room temperature is not very big, the heat dissipation rate of fish meal will be more slow. If the fish meal is directly packaged and stacked, it is easy to generate heat phenomenon, and even spontaneous combustion will occur in serious cases, so fresh fish meal must be cooled to room temperature before storage. The role of the Cooler is to cool the fish meal at a higher temperature directly to room temperature. According to the requirements of different production lines, we are equipped with three types of coolers, which will be described below.

1.Cooler with air & water cooling

The Cooler with air & water cooling is composed of a cylindrical shell and a spiral shaft, half of the spiral shaft is welded with a spiral pipe, inside which the cooling circulating water is passed, the other half is welded with stirring wheel blades. The spiral shaft and the spiral tube on the shaft adopt hollow structure with cooling water inside. The stirring wheel blades stir the fishmeal while the impulse dust collector draws air, so that the fishmeal can fully contact with the air. After the outside natural wind enters the cooling cylinder, it is constantly drawn out by the de-dusting fan to form the cooling circulating wind, thus achieving the purpose of cooling.

The high temperature fishmeal enters the machine through the inlet and is continuously stirred and thrown under the action of the spiral tube and stirring wheel blades with cooling circulating water inside, and the heat is continuously dissipated. And at the same time, the water vapour dissipated is immediately taken away by the cooling circulating air, so that the temperature of the fishmeal is continuously reduced and pushed to the outlet under the action of the stirring wheel blades. So this cooler is to achieve the purpose of cooling fish meal by combining water cooling with air cooling.

2.Air cooler

For larger production lines, in order to achieve better cooling effect, we usually equip with a air cooler and a water cooler. The air cooler is not very different from the cooler with air & water cooling in appearance, but the air cooler is composed of a cylindrical shell, a spindle welded with stirring wheel blades and a impulse dust collector. The fishmeal is fed from the power end, and is continuously stirred and thrown by the stirring wheel blades in the process of passing through the cooler. The heat is constantly dissipated, and the water vapor is immediately taken away by the de-dusting fan. The bag structure of the impulse dust collector can ensure that the fishmeal is not sucked into the air-suction pipeline, causing the air-suction pipeline to be blocked, thus achieving a good cooling effect.

3.Water cooler

The water cooler is composed of a cylindrical shell and a spiral shaft welded with a spiral pipe. The spiral shaft and the spiral pipe on the shaft adopt hollow structure, and the cooling water is passed inside. High temperature fishmeal from the inlet into the machine, are constantly stirring and thrown under the action of spiral pipe, the fishmeal is in large contact with the spiral tube,so that the heat is continually dissipated by indirect heat exchange. At the same time, the water vapour dissipated is immediately taken away by the cooling circulating air, so that the temperature of the fishmeal is continuously reduced and pushed to the outlet under the action of the spiral pipe, achieving the purpose of cooling the fishmeal.

Installation collection

Product detail pictures:

Related Product Guide:

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Quality Inspection for Fish Processing Equipment For Poultry Feed - Cooler (Competitive Price Fish Meal Cooler Machine) – Fanxiang , The product will supply to all over the world, such as: New Delhi, Lithuania, India, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.