Special Price for Fishmeal Processing Line - Automatic packing system (Manufacturers Direct Selling Automatic Packing Machine Full System) – Fanxiang

Special Price for Fishmeal Processing Line - Automatic packing system (Manufacturers Direct Selling Automatic Packing Machine Full System) – Fanxiang Detail:

working principle

Fish meal must be packaged before storage or delivery. The packaging bag generally uses polyethylene woven bag. Packaging work can be divided into two kinds of mechanical packaging and manual packaging. Manual packaging equipment is very simple, only need scales and portable sewing machine and other simple tools. And the degree of packaging automation depends on the size of the factory’s production and processing capacity. The mechanical packaging with higher degree of automation has been adopted by more and more manufacturers. The system is suitable for assembly line operation, compact structure, less occupation area, accurate weighing and measurement, which can improve labor efficiency, reduce labor, and save production cost. The bagged finished fish meal after sealing can be sent directly to the warehouse for storage.

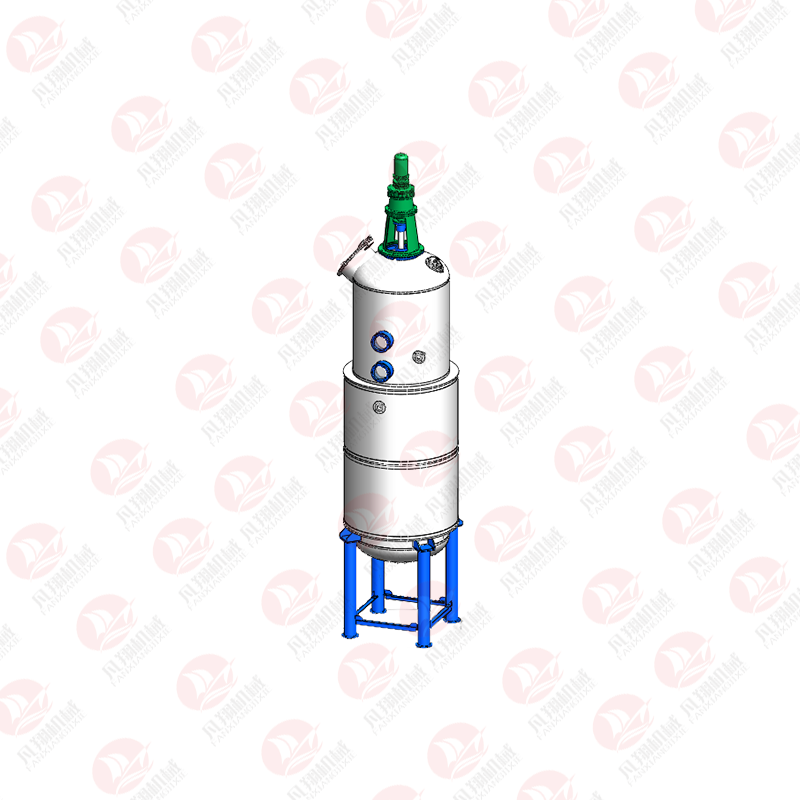

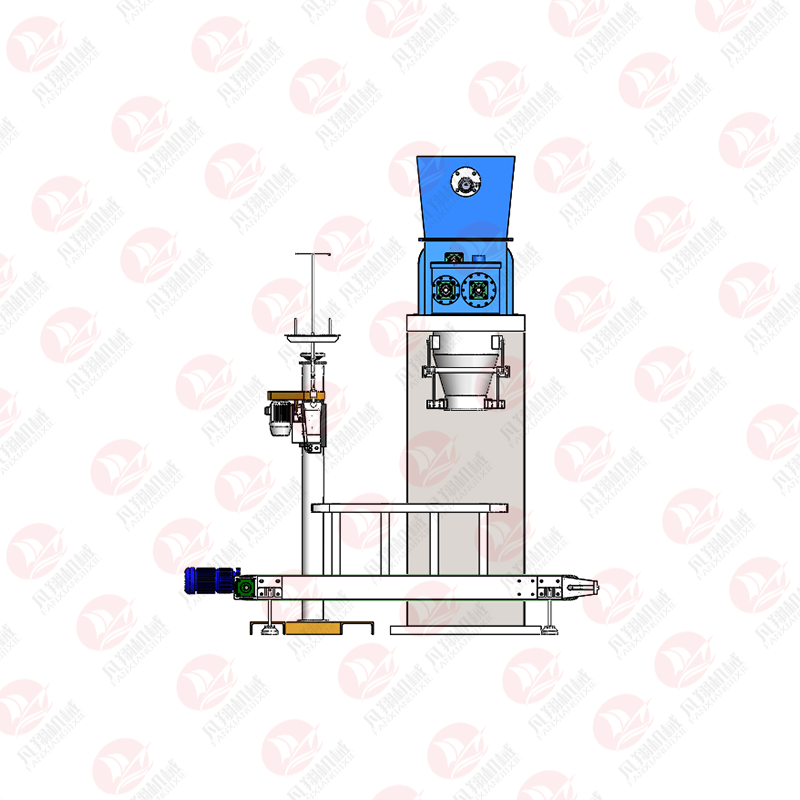

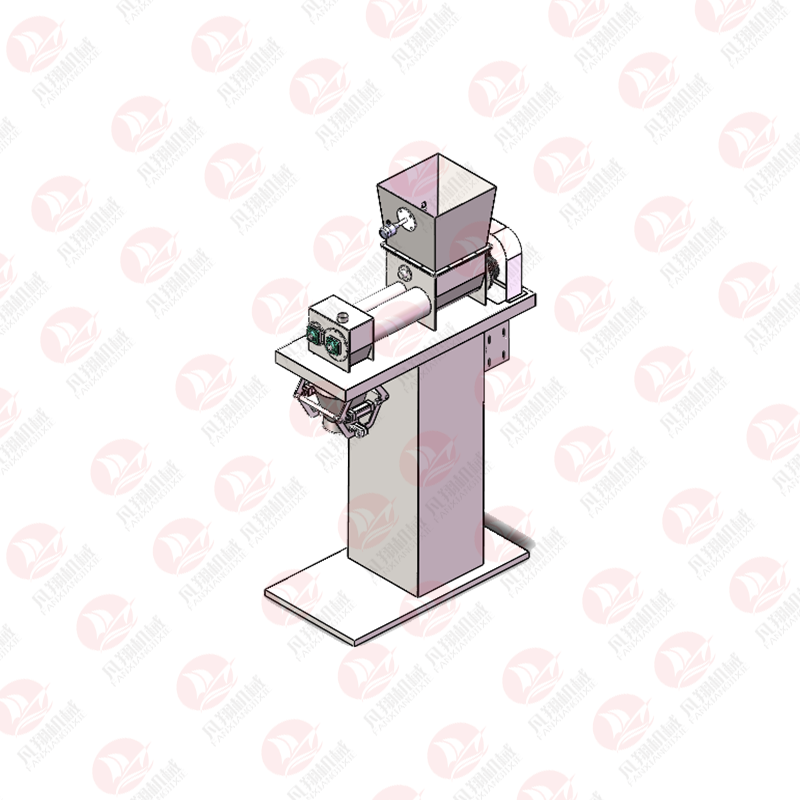

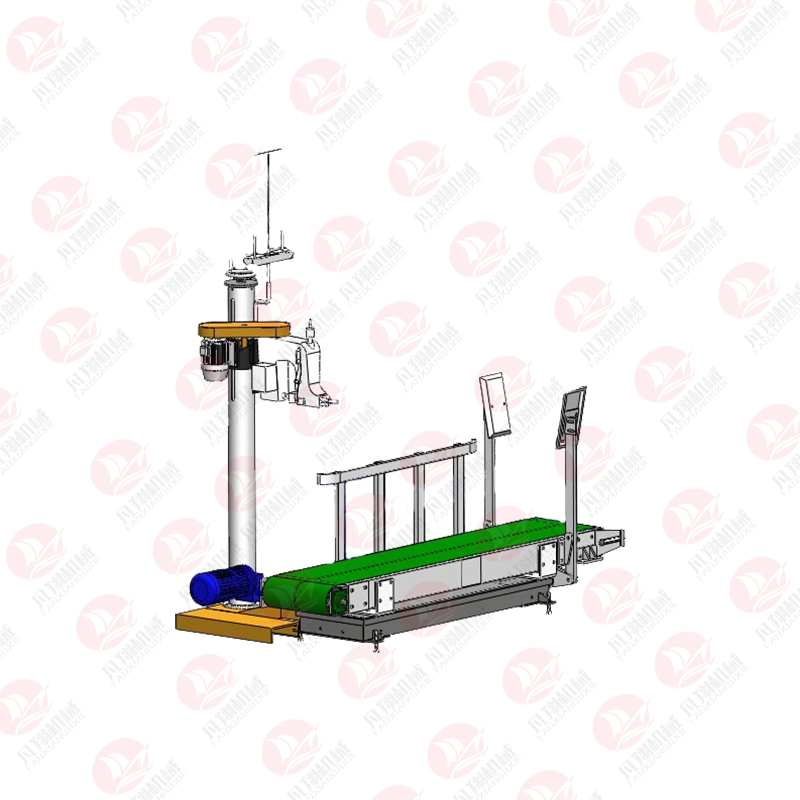

The automatic packing system is mainly composed of packing screw conveyor, automatic quantitative packaging scale, belt conveyor with weighing device & display, and sewing machine. Its weighing and packing process is to use the program control function of the weighing display controller to realize the feeding control of the packing screw conveyor, so as to achieve the accurate measuring effect. After finishing the weighing, the bags are transferred to the bag sewing machine through the belt conveyor to complete the sealing work. The finished fish meal in bags after sealing can be directly sent to the warehouse for storage. This automatic packing system can also meet the needs of other powdered materials, which is very popular in both domestic and international markets.

Installation collection

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Special Price for Fishmeal Processing Line - Automatic packing system (Manufacturers Direct Selling Automatic Packing Machine Full System) – Fanxiang , The product will supply to all over the world, such as: Maldives, Hungary, Mauritius, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!